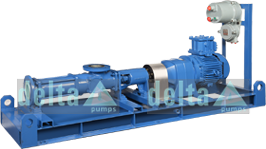

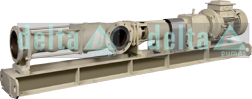

Single Screw Pumps / Progressing Cavity Pump ( Series D1S )

A screw pump is a positive-displacement (PD) pump that use one or several screws to move fluids or solids along the screw(s) axis. In its simplest form, a single screw rotates in a cylindrical cavity, thereby moving the material along the screw's spindle.

The pressure capabilities of the pump are a function of the number of cavities. Delta progressive cavity pumps are available in a wide variety of materials - cast iron or stainless steel wetted parts and 10 standard elastomeric materials. Delta’s versatile progressing cavity pumps are rugged, compact and highly efficient. Fluids, which are delicate, shear sensitive or abrasive, low or high viscosity, with fibers, with high air content or large solids, can be conveniently handled by Delta’s progressive cavity pumps.

Working Principle:

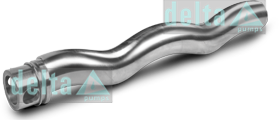

- The pumping elements are rotor and stator.

- The single helical rotor rolls eccentrically in a double threaded helix stator of twice the pitch length.

- A series of sealed cavities 180° apart are created that appear to progress from suction to discharge during one rotation of rotor.

- The opposing cavities fill and empty simultaneously resulting in a pulsation less flow.

- The fluid travels axially with relatively low velocity and minimal agitation.

- The stator is made of a resilient elastomeric material and bonded to the stator tube.

- The important feature of the pumping principle is the ability to handle slurries and solid particles. The elastomeric stator also permits passage of solid particles due to elastomeric deformation.

Salient Features:

- Sturdy drive design provides strength for rigorous continuous operation.

- Unique joint design is very simple and maintenance free joint, does not require replacement due to wear and tear, common in other joint designs.

- Maintenance friendly design of the pump enables complete maintenance of the pump without removing the suction and discharge pipelines.

- Close coupled models with built-on speed reducers offer compact pumping unit.

- Stators are available in a wide range of elastomeric.

Typical Parameters:

- Capacity: 5 to 2700 lpm

- Differential Pressure: 24 bar max

- Temperature: from cryogenic to 100°C

- Viscosity range: 1 to 100,000 cp

Drive arrangements possible:

- Direct drive with motor.

- Through gear box.

- V-belt pulleys.

- Variable speed drives.

- Special drives such as hydraulic, with I.C. engines.